According to the International Energy Agency’s “Net Zero by 2050” report, electrifying the power sector represents the most significant potential decrease in emissions reduction on the road to reaching net-zero emissions. As a result, the pace of development for wind projects will be multiplied by 4x between 2020 and 2030 — including an 18x growth for offshore wind projects — representing $810 billion in investments by then. Longer-term outlooks forecast the wind industry to grow tenfold in the next 30 years.

Though the wind industry continues to grow at a sustained pace, innovation in maintenance remains behind the curve, posing operational, financial and safety challenges for operators of older turbine models and newer, larger models.

The existing global wind fleet is aging, which increases global maintenance costs and puts pressure on operators. As the fleet ages, ensuring that increasingly frequent maintenance operations occur on schedule and at a reasonable cost is a real challenge. And as blades get larger — much larger — these operations get more complex, time-consuming, and risky.

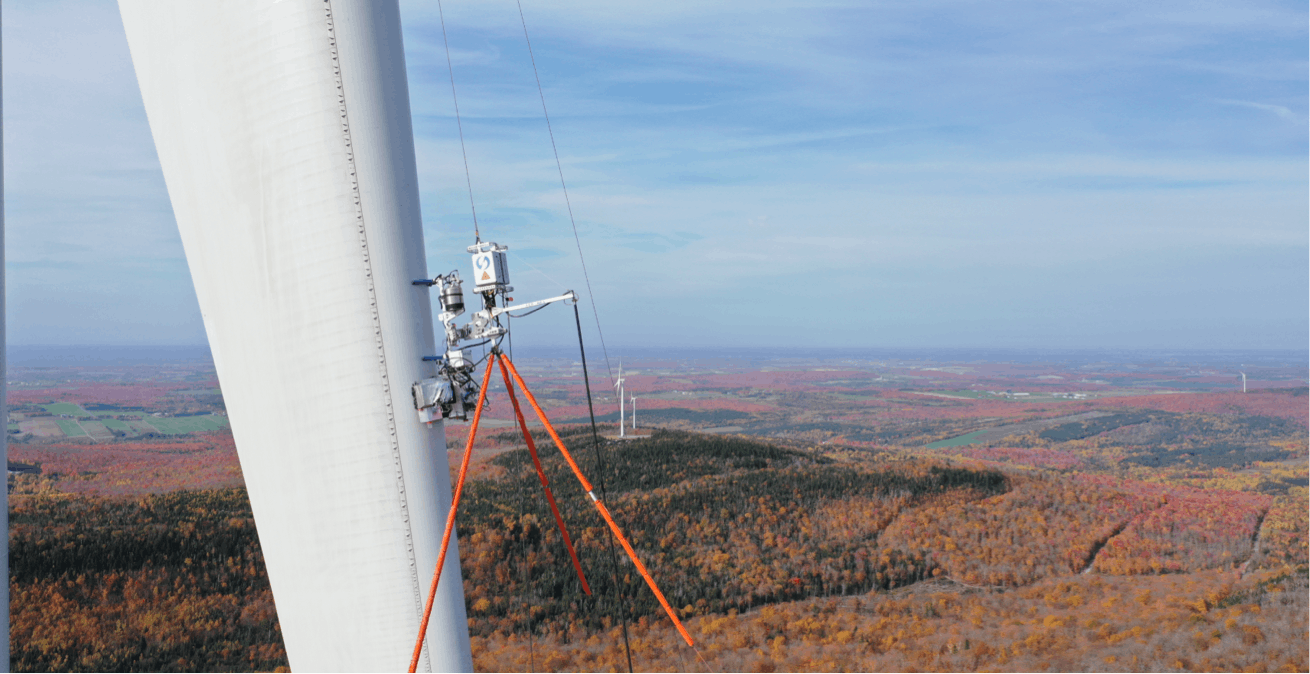

As the pace of development for wind projects accelerates, scaling wind energy requires rethinking how we manage and maintain wind farms. Though sensors can monitor performance in real-time and remotely detect some failures, and drone-led aerial inspections can detect external structural issues, not only are those solutions inherently limited, but they also require human operators to perform the actual “hard work” of maintenance such as cleaning, reparation and replacement.